Thermoelectric devices have recently raised interest as a compelling solution for electricity generation by harvesting heat dissipated from heating systems, automotive engines, power plants, solar farms, and smartphone devices. In thermoelectric generators (TEGs), p- and n-type thermoelectric materials are sandwiched between two metallic junctions. When a temperature gradient is applied between the two junctions, charge carriers diffuse from the hot to the cold junction, thereby generating electrical current and voltage. In our Omegalab, we are developing p- and n-type organic and hybrid organic/inorganic thermoelectric materials that are compatible with low-cost scalable processes such as printing and coating methods. We aim to realize high performance and low-temperature processed thermoelectric organic and perovskite materials by comprehensively understanding the material characteristics and materials design.

1. Organic Thermoelectrics

Development of efficient and versatile organic thermoelectrics using organic semiconducting/conducting materials with novel functionality, such as extremely deformable/stretchable and self-healable/recyclable polymers and small molecules. Based on these materials, we are demonstrating wearable and skin-attachable thermoelectric devices via high-throughput printing techniques including doctor-blade, ink-jet, and 3D printing.

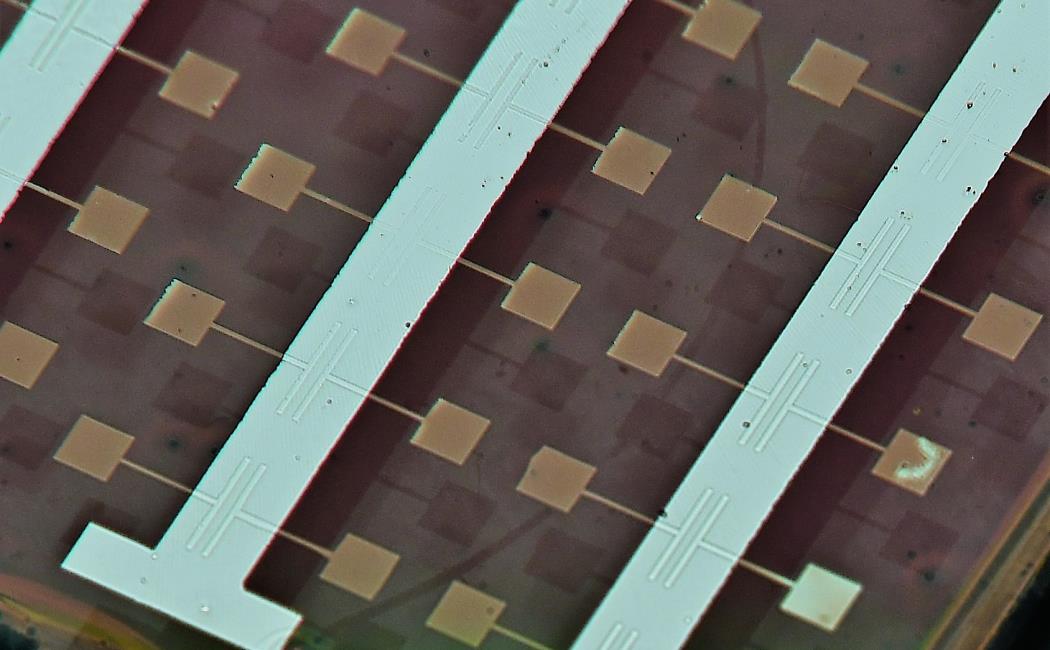

2. Perovskite Thermoelectrics

The versatile nature of hybrid halide perovskites has already resulted in a multitude of applications apart from photovoltaics. The ultralow thermal conductivity and high seebeck coefficient of these hybrids make them suitable candidates for future thermoelectrics. Our focus in this project is to explore the thermal transport properties of these hybrids for efficient thermal management and device applications.

3. Materials Properties

In order for thermoelectric materials to be readily available in the market, there are several challenges to overcome. In the Omegalab we are focusing on understanding the electronic and mechanical properties of thermoelectric materials in order to improve performance and process-ability for large-area applications. In addition, we are exploring the effects of doping as well as the use of different systems to improve the stability of the materials under different stress conditions. Lastly, we aim to make the materials suitable for deposition with high throughput techniques such as an inkjet or 3D printing.